Is Chip Cooling the Answer to Data Center Sustainability?

After receiving a $1.8M COOLERCHIPS grant, Purdue University looks to revolutionize data center cooling with innovative chip cooling methods.

Data centers are notorious for their high energy consumption, with cooling equipment accounting for nearly 30% of the total power usage. Data centers with processor thermal designs can generate 20 to 50 MW of heat, according to Hugh Hudson, a data center market manager for Daikin Applied, a commercial cooling company. In light of this, researchers are exploring chip cooling methods to mitigate the energy burden and improve efficiency in data centers.

The U.S. Department of Energy's COOLERCHIPS program recently granted Purdue University a substantial award to advance its pioneering efforts in developing more efficient cooling solutions for data centers. With a focus on reducing energy usage and enhancing cooling efficiency, Purdue aims to revolutionize the way chips are cooled.

The Challenge of Cooling Chips in Data Centers

The exponential growth of data centers in an ever-increasing digital world has led to significant investments in research, particularly in chip cooling. The cooling of microchips — major energy-consuming components in data centers — alone can account for 40% of overall energy usage in a data center, and the demand for water as a cooling resource is becoming a widespread problem. Organizations are now prioritizing water conservation as part of their sustainability efforts.

Yongsuk Choi, chief strategy and infrastructure officer, at Empyrion DC, a digital infrastructure platform company, says artificial intelligence (AI) and machine learning (ML) applications are really "shaping the data center industry."

"Such growth in high-capacity computing has caused a dramatic 200% increase in rack density to 20-30KW per rack today," Choi told Data Center Knowledge. "This is where microchip cooling comes in. Compared to conventional air cooling, which requires cooling of the entire service, microchip cooling is much more targeted and addresses the direct source of heat at the chip level, achieving faster cooling with less energy consumption. We foresee greater adoption of microchip cooling by data center operators."

COOLERCHIPS Goal: Develop 'Highly Efficient' Cooling Technologies

To address the challenges and explore novel approaches to chip cooling, the DOE launched the Advanced Research Projects Agency-Energy (ARPA-E) Cooling Operations Optimized for Leaps in Energy, Reliability, and Carbon Hyperefficiency for Information Processing Systems — or COOLERCHIPS — program. This program aims to drive advancements in cooling technology through collaboration between academia, industry, and government national labs.

In May, the COOLERCHIPS program issued $40 million in funding to support research in this field, with the goal to reduce the environmental impact of data centers by developing "highly efficient and reliable cooling technologies."

Purdue University's Pioneering Chip Cooling Research

Purdue University, a recipient of a $1.8 million grant under the COOLERCHIPS program, is at the forefront of developing innovative chip cooling solutions. The university's research goes beyond cooling semiconductor microchips and packaging, aiming to optimize heat transfer among data center components. By enhancing thermal performance and reducing pumping power, Purdue's goal is to revolutionize the way data centers are cooled.

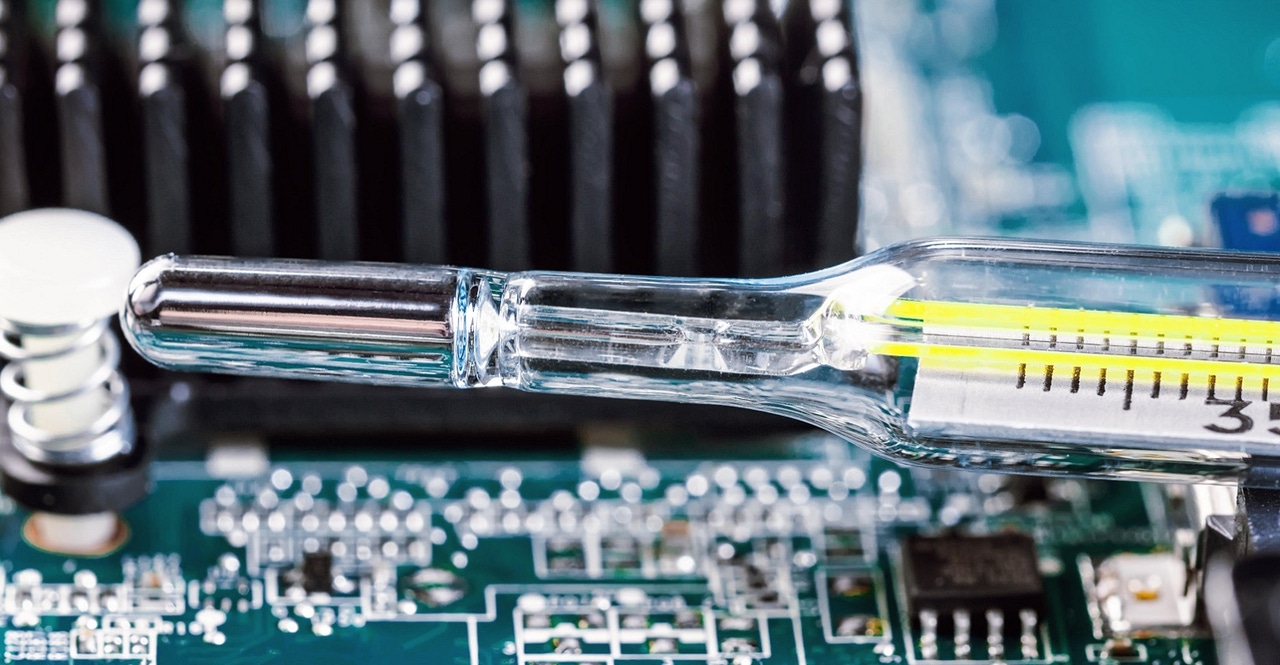

Two-Phase Jet Impingement Cooling

The Purdue team was looking at more "aggressive technologies" than what's in use, according to Tiwei Wei, assistant professor of mechanical engineering and the project's lead principal investigator.

One of the key research areas at Purdue University involves two-phase jet impingement cooling. This approach utilizes microchannels filled with liquid integrated directly within the microchip packaging. As the chip generates heat, the liquid boils, and the resulting vapors carry the heat away from the chip. The steam then condenses and is recirculated into the chip, enabling passive cooling without the need for a pump.

Direct Liquid Contact and Gravity-Driven Flow

Purdue's innovative solution also involves direct liquid contact with the chip's surface, eliminating the need for thermal interface materials. A layer of silicone on the backside further enhances cooling efficiency. By utilizing the gravity of the liquid, Purdue aims to minimize power consumption by placing the condenser at a higher position and allowing gravity to drive the flow into the chips. This approach optimizes chip cooling while reducing energy consumption.

"Our solution is basically looking at impinging the data cooling with some surface enhancement and whipper extraction technologies," said Wei. "From the chip level, the cooling is directly on the chip."

Meeting the Cooling Demands of High-Performance Chips

Traditional cooling methods in data centers, such as cooling at the room level, are no longer sufficient to meet the demands of modern high-performance microchips. To effectively handle heat generation, data centers now rely on a combination of air-cooling, direct-liquid, and immersion cooling systems. Enhancing thermal performance and reducing pumping power contribute to energy savings and enable data centers to accommodate the higher transistor densities of new computer chips.

By developing more efficient cooling solutions for chips, Purdue University's research aligns with the goal of the COOLERCHIPS program.

Adopting a new class of efficient cooling systems is vital, DOE Secretary of Energy Jennifer Granholm said in a statement, because soaring temperatures and increasing heat waves are impacting data centers. "Data centers which connect critical computing and network infrastructure" must be kept at certain temperatures to remain operational, she added.

However, industry veteran and founder and CEO of Edge Cloud Link Yuval Bachar notes that there are other alternatives currently in use to ease the pain points of data centers. Bachar sees harnessing the power of hydrogen as key to data center energy issues. He's launched a unique data center model that harnesses the power of hydrogen. His data centers would house 4,000 traditional servers in about 100 square meters.

"I think we can get to 5% overhead with traditional cooling solutions without the need for emissions cooling," said Bachar.

But Bachar and Purdue aim for the same result: reducing cooling costs. Purdue's efforts align with the broader objective of the COOLERSHIPS program, which seeks to create energy-efficient cooling solutions while reducing carbon footprint. It also seeks innovation that is reliable and cost-effective.

Conclusion

Efficiently cooling chips in data centers is a critical factor in improving overall energy efficiency and reducing costs. Purdue University's research supported by the COOLERCHIPS program aims to revolutionize chip cooling methods through innovative approaches such as two-phase jet impingement and direct liquid contact.

By optimizing cooling efficiency, data centers can achieve substantial savings and make significant progress toward a more sustainable future.

Read more about:

Chip WatchAbout the Author(s)

You May Also Like

.jpg?width=700&auto=webp&quality=80&disable=upscale)