Eric Monsen is president of Monsen Engineering Co. With over 30 years of Commercial HVACR Energy Conservation knowledge, his focus is on how to make equipment run to top performance.

ERIC MONSEN

ERIC MONSENMonsen Engineering Co.

Most people in the data center/facilities management industry have never heard of oil fouling. The Heating Ventilation Air Conditioning & Refrigeration (HVACR) industry has long known that it exists, but little could be done about it. Often equipment installations were designed slightly over-sized to accommodate for this efficiency loss. Today, manufacturers are introducing “Oil-Less Compressors” as a way to eliminate this problem. Through technological advances, there are now ways to solve this problem.

What is Oil Fouling?

Oil fouling occurs in most HVACR systems almost immediately. It is defined as “the accumulation of unwanted oil deposits on the inside of the cooling coil system and other major components restricting and inhibiting proper heat transfer exchange of an HVAC system. . .during the refrigerant compression process, oil migrates from the compressor to the coil system contaminating the metals that transfer heat,“ according to the ASHRAE Refrigeration Handbook, 1998, Chapter 6.7. Oil Fouling occurs on the inside of the coils, where technicians don’t have access.

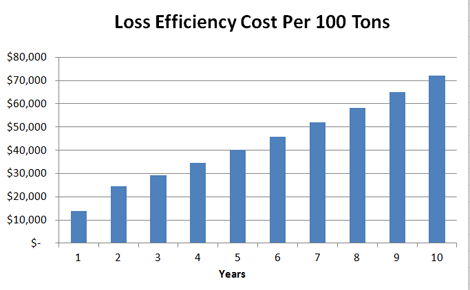

Why this should be of interest? “Oil fouling” is robbing the equipment in your facility of energy and life extension. According to ASHRAE, "Oil fouling will cause a loss of about 7 percent efficiency the first year, 5 percent the second year and 2 percent per year the following years. Performance is degraded by as much as 30 percent due to build-up of lubricants on internal surfaces.”

What Does This Mean to a Data Center?

This is a substantial percentage of efficiency loss. This equates to real dollars in multiple ways. First, your equipment runtime will increase to reach its’ target temperature. Additional runtime equates to additional electricity costs, equipment repairs and maintenance. Wear out and breakdowns will cost the facility even more money in unplanned service calls and untimely replacements expenses. Secondly, lost capacity can also lead to additional cooling equipment being purchased in order to reach mandatory temperature. Redundancy can be lost and PUE goes way up.

Now let’s do some math:

In summary, a system which is “oil fouled” must work harder to reach necessary temperatures to keep the data center equipment from breaking down. Longer run times result in the use of more power and less useful life from your equipment. Lost capacity will lead to additional capital expenditure.

The good news is that technology is on our side. New products are now on the market to eliminate this problem. My company is constantly on the lookout for new technologies that will lower the costs of running facilities and extend equipment life, especially in mission-critical data centers, and we work with customers to address these issues and lower the company's operating costs.

Industry Perspectives is a content channel at Data Center Knowledge highlighting thought leadership in the data center arena. See our guidelines and submission process for information on participating. View previously published Industry Perspectives in our Knowledge Library.