Southland Industries at Hyatt Regency in Reston Town Center.

Mike Kilkeary is an Associate Principal Engineer at Southland Engineering.

Data center cooling design is one of the most diverse aspects in what otherwise is an industry built on commonality. Despite a common goal of cooling server and heat generating equipment, the factors that drive mechanical cooling system selection differ wildly for each owner, developer, operator, and end user. Factors such as initial cost, operating efficiency/cost, speed to market, redundancy, reliability, scalability, flexibility, climate control/SLA compliance, water use, equipment space, and maintenance are all weighed differently and have various levels of influence when selecting a system. Today, new technologies offer efficiencies that are reducing both initial costs and energy usage for data center operators.

Out of those factors listed above, initial cost and operating efficiency/cost are often the primary drivers for data center cooling design. Naturally, the question that follows is, ”which cooling system would minimize initial cost and maximize operating efficiency, while scoring well in all the other categories?” One emerging technology that meets these criteria is air cooled chillers with integrated waterside economizer. Integrated waterside economizer provides the ability to create chilled water using just cold air during ideal ambient conditions with no mechanical cooling, all integrated into the standard sequence of controls for the air-cooled chiller.

Air-cooled chillers, while very competitive from a first cost perspective, traditionally have not performed well with regards to energy consumption while operating in mechanical cooling mode. With a lack of an integral waterside economizer option, air-cooled chillers were almost unusable in most climates, especially those with significant cold weather hours where an economizer would provide significant mechanical cooling relief.

There are three major changes to air cooled chillers that have occurred in the last decade that will change the course of their use in the data center market: the addition of an integral waterside economizer on the chiller, use of screw or magnetic bearing centrifugal compressors in lieu of scroll compressors, and variable speed operation of compressors and condenser fans. Each of these changes was made to optimize the energy performance, but the most significant has been the ability to have the waterside economizer as an integrated part of the chiller instead of as an appendage system. This replaces having to use dry coolers or a cooling tower system as means for waterside economizer, saving mechanical equipment space, simplifying the system control, and eliminates the water use and heavy maintenance that comes with a cooling tower.

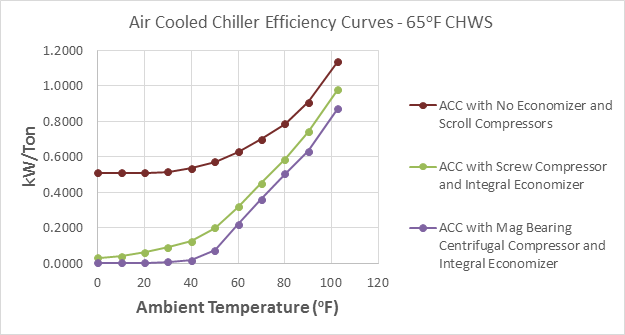

From an operating efficiency perspective, the changes in air-cooled chillers have been significant. Figure 1 below shows three air cooled chiller selections, one with traditional scroll compressors and no integral economizer, one with screw compressors and an integral economizer, and the last with a magnetic bearing centrifugal compressor and an integral economizer. The effect of the screw and magnetic bearing centrifugal compressors can be seen clearly at temperatures above 80oF, and most prominently at peak data center design temperature for the Mid-Atlantic region of 103oF. The drop at peak from 1.17 kW/ton with the traditional air-cooled machine to the 0.84 kW/ton for the magnetic bearing centrifugal compressor machine, a 29% decrease, is especially significant for peak Power Use Effectiveness (PUE) calculations and generator sizing.

Figure 1: Operating efficiency curves for various air-cooled chiller selections

However, the real energy savings occur in the partial and full waterside economizer modes at temperatures below 60oF. In data center applications, the use of elevated chilled water supply temperatures between 60-70oF is common. For climates that experience significant hours below 60oF, such as the Mid-Atlantic region with a whopping 5022 hours out of a possible 8760 yearly hours (57%), the opportunity exists to obtain significant operating energy savings by running partial to full waterside economizer. This is highlighted in Figure 2 with the area under the curve, shaded in orange, showing the energy saving potential with use of the integrated waterside economizer.

Figure 2: Energy saving potential with use of integrated waterside economizer on air cooled chiller

Figure 2: Energy saving potential with use of integrated waterside economizer on air cooled chiller

While the improvements in energy from a traditional air-cooled chiller to the current designs with integrated economizer were immediately apparent, the pricing of air cooled chillers deterred adoption. As with any new technology, the cost of air cooled chillers with the new compressor technology and integrated economizer was very high. The relative first cost compared to rest of the cooling technology market was so high that it was almost impossible to recommend using them, and undermined the potential long-term energy and operating cost savings.

However, in the last two years, with many reputable chiller manufacturers stabilizing their assembly process and offering an air-cooled machine with integral economizer, heavy market competition has reduced prices significantly. The pricing has dropped to levels below what would a water-cooled chiller and cooling tower combination system would cost, with all the benefits of a chiller water system, and no daily water use. No daily water use is becoming a greater point of emphasis as water costs continue to rise and drought conditions become more common in many locations.

In addition to excellent annual operating efficiency and very competitive first cost pricing, the air-cooled system will score well in every other significant driving factor for mechanical system selection. The large amount of chiller manufacturers in the market will continue to drive down chiller pricing and speed to market. The system is extremely scalable, and allows Owners the option to “plug and play”, adding chillers and capacity to the overall system as required. The equipment space required is very small, no significant roof penetrations over data halls are required, and it’s a reliable technology with standard parts for easy maintenance. These factors, combined with ability to have a system with waterside economizer with zero daily water use, will allow air-cooled chillers with integral economizer to create a market disruption in data center cooling system selection.

Opinions expressed in the article above do not necessarily reflect the opinions of Data Center Knowledge and Informa.

Industry Perspectives is a content channel at Data Center Knowledge highlighting thought leadership in the data center arena. See our guidelines and submission process for information on participating. View previously published Industry Perspectives in our Knowledge Library.