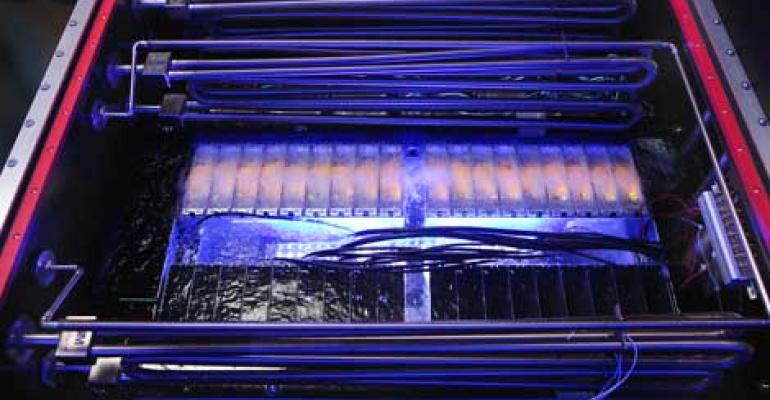

Earlier this month 3M unveiled a proof-of-concept for open bath immersion (OBI), a passive two-phase cooling technique which uses a boiling liquid to remove heat from a surface and then condenses the liquid for reuse, all without a pump. Here's a closer look at the demonstration project at 3M's lab in Minneapolis, which submerged ICE-X supercomputing hardware from SGI running Intel chips.

The servers are immersed in 3M’s Novec, a non-conductive chemical with a very low boiling point, which easily condenses from gas back to liquid. (Photo: 3M)

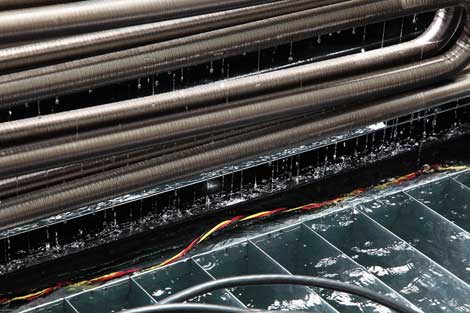

The vapor generated by the boiling Novec rises to a condenser integrated into the tank and cooled by waters, and then condenses back to liquid for reuse. (Photo: 3M)

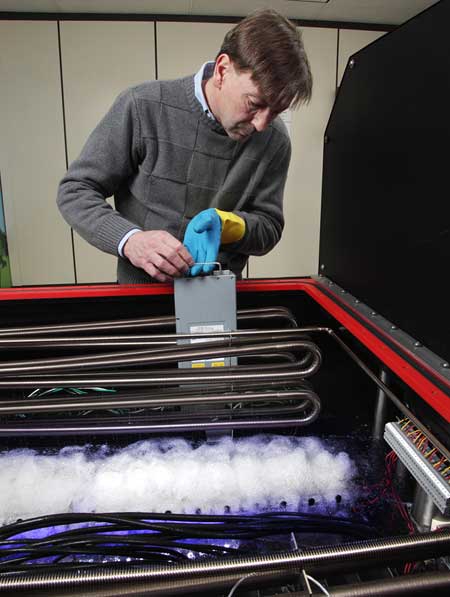

One of the big differences in immersion cooling involves maintenance. In this photo, a 3M technician wearing a rubber glove removes a server from, the pool of Novec coolant. (Photo: 3M)