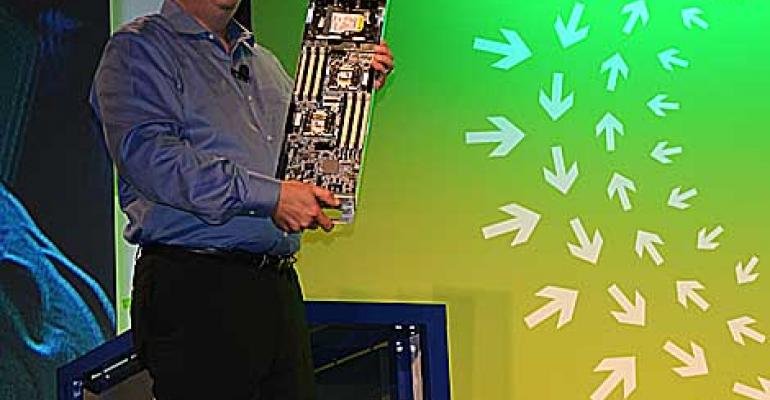

Glenn Keels, Director of Marketing for HP's Hyperscale business, unveils new HP product that works with Open Compute standards. (Photo: Colleen Miller)

SAN ANTONIO - The Open Compute Project is ready to shake up the world of data center racks. The open source hardware project today outlined plans for Open Rack, which will seek to set a new standard for rack design for hyperscale data center environments.

The biggest change is in the width of the server itself. Open Rack provides a 21-inch wide slot for servers, expanding upon the 19-inch width that has long been the standard for data center hardware. The wider form factor will create more room for improved thermal management, as well as better connections for power and cabling.

"Racks may not sound so sexy, but they're a critical component in all data centers," said Frank Frankovsky, VP of Hardware Design and Supply Chain for Facebook, which founded the Open Compute Project last year. "We are ditching the 19-inch rack standard. We've forced ourselves into this 19-inch width, and we end up with what I call 'racks gone bad.'"

Unified Power, Mechanical Interfaces

The Open Rack design, which was unveiled today at the Open Compute Summit in San Antonio, also offers an innovative approach to power management. The design features busbars supplying 12-volt power to servers, eliminating the need for individual power supplies for each server. Open Rack also offers standard interfaces for mechanical and electrical components.

Frankovsky said the wider form factor will provide more room for adequate airflow within the chassis, making it easier to remove heat from the server. With the 19-inch design, "components wind up in other components' exhaust paths," resulting in inefficient thermal design.

The rack frame will remain 24 inches wide, Frankovsky said, so the Open Rack design won't force data center operators to rework their entire data centers.

The Rack as a Chassis

Open Rack represents the latest attempt to treat the rack as a chassis, shifting some components of power and cooling from the server level to the rack level. The OCP effort has gained support from two key players in the server ecosystem. Dell and HP were both on hand at today's Summit to show off new servers loaded into the Open Rack prototype.

HP's Glenn Keel said the company's new Open Rack-ready design, which it developed for Facebook, which used 2 Xeon E5 processors and offered power savings of up to 50 percent compared to standard racks, Keel said. Dell's Forrest Norrod showed off designs from Dell's Data Center Solution (DCS) unit that allow clients to mix different types of servers and storage in the same Open Rack row.

"Open Rack is one of the most promising developments in the scale computing environment," said Keel.

The effort to shift design components to the rack level is reminiscent of some of the approaches used in blade server chassis. Unfortunately, most blade server chassis and components featured proprietary features that were focused on lock-in rather than interoperability.

"I consider this blades done right," said Frankovsky. "No more power supplies in servers or storage devices. Blades held great promise for aggregating IT equipment,but were designed in an artificial, properietary way."

The Open Rack effort isn't the only initiative seeking to remake the data center rack. As the Open Compute team was developing Open Rack, three large Chinese Internet companies - Tencent, Baidu and Alibaba - were working on a design to solve similar problems. The two teams have been comparing notes and sharing ideas, but haven't yet officially merged the designs.